Leader: Prof. DSc Marek Molenda

Team: Prof. DSc Józef Horabik; Assoc. Prof. DSc Mateusz Stasiak; DSc Joanna Wiącek; PhD Piotr Parafiniuk; PhD Rafał Kobyłka; MSc Maciej Bańda

In the frame of the topic 1 we conduct research mainly in two directions: numerical modeling of mechanical phenomena present in technologies of particulate materials and laboratory investigations of physical properties of plant particulate materials and food powders.

Agriculture and food industry are, next to chemical and pharmaceutical industries the largest producers and users of the granular materials. Two basic conditions have to be fulfilled by equipment for storage and processing of granular materials: predictable and safe operations and obtaining a high quality of final products. Recently observed increase in application of granular materials in numerous industries resulted in intensified efforts at understanding the complex and so far unexplained behaviors of those systems. Mechanical characteristics of agro/food powders and granular materials are strongly dependent on moisture content and individual grains are highly deformable as compared to mineral powders. Such a material cannot be treated as rigid and in design or modelling of processes elastic behavior should be considered. Cereal grains are nearly ellipsoidal in shape and when forming bedding under conditions of gravity, in general produce considerable anisotropy that results in uneven load distribution on storage structure and disturbances in flow. Food powders of relatively small grains pose difficulties in processing due to variations of flowability and tendency to cake. Recently, flowability has gained interest of industry as a measure of quality of product.

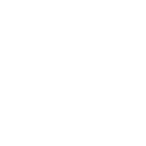

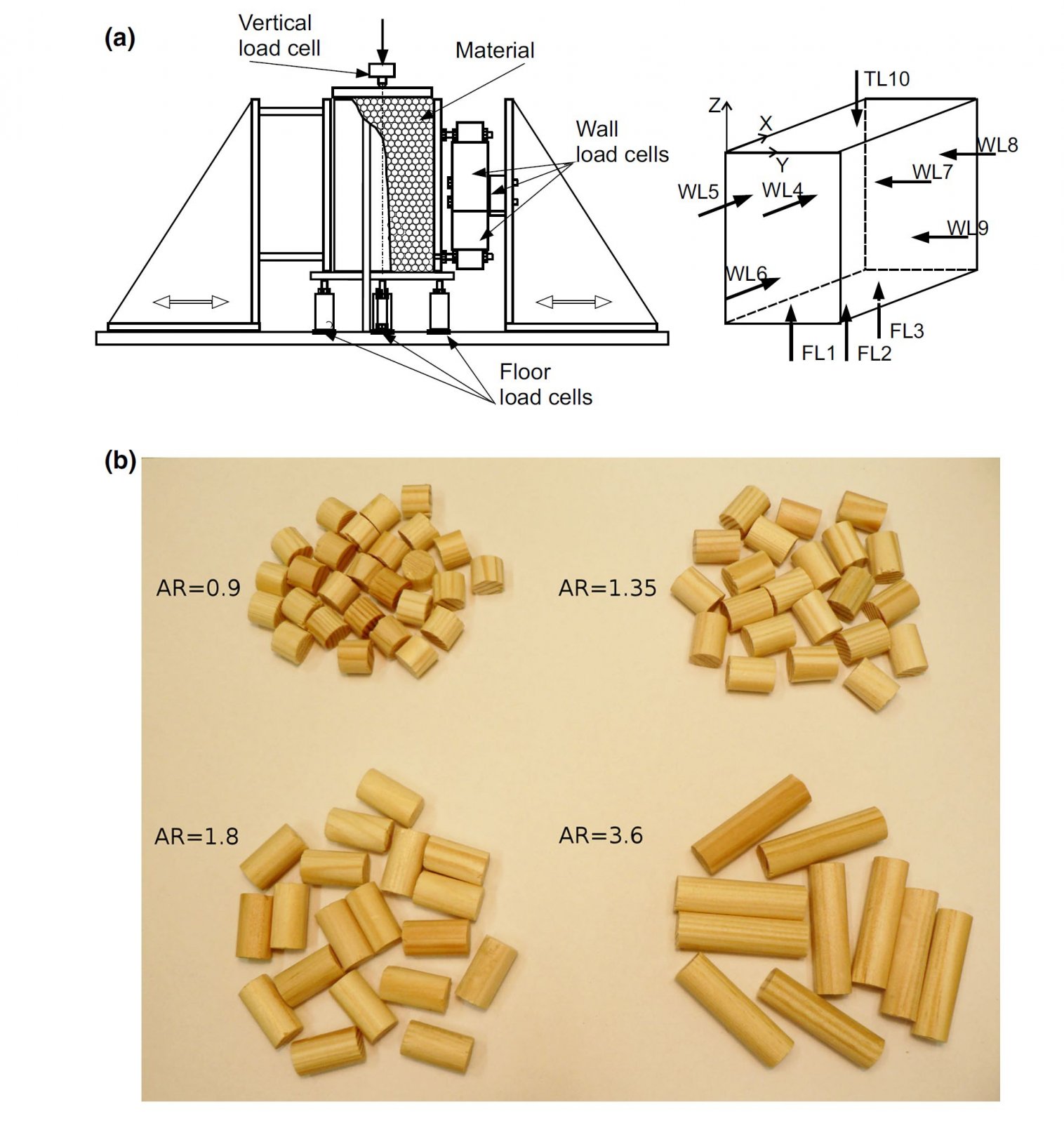

Packing structure, load transmission and flowability are currently in our immediate interest. In examinations we use laboratory methods as well as numerical ones. Discrete element method is particularly intensely used as it is a modern tool that proved to be efficient while still under development.