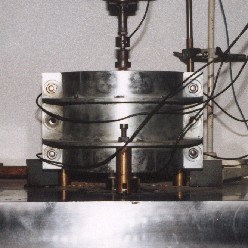

RST-01 Ring Shear Tester

- Two measurement chambers: 1 – shearing surface 235 cm2, volume 900 cm3; 2 – shearing surface 85 cm2, volume 200 cm3

- Maximum measurable shearing force: 400 N; maximum measurable consolidation force: 500 N; shearing speed range: 0.05-30 mm/minPomiar siły ścinania do 400 N, pomiar siły konsolidującej do 500 N, prędkość ścinania: 0,05- 30 mm/min

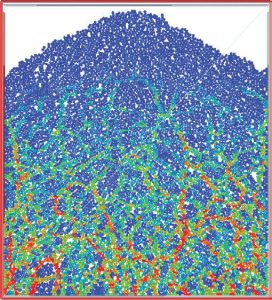

Examples of use:

- Determination of flowability of food powders

- Determination of the shear strength of bulk materials

- Determination of the friction coefficient against construction materials

- Determination of sample density

- Determination of the geometry of outflow from silos

- Determination of processing parameters for design of storage containers

Jenike’s direct shearing devices for different granule sizes

Jenike’s direct shearing devices for different granule sizes