In the field of agricultural sciences, numerical modelling has proven to be a valuable tool in finding solutions to practical and scientific issues. Such models are necessary to understand the structure related properties of plants, like fruits and vegetables, and bring, in the next step, possibilities of extension by nano-structural features (like cell wall composition). This knowledge will be useful for engineering and improve fruits and vegetables quality.

The basic idea behind finite element method (FEM) is subdivision of a spatial domain of the problem into a simpler parts called the finite elements. The solution in global domain is obtained as a result of assembly of local solutions for the finite elements. Finite element method allows studies of systems with large complexity, irregular shapes and nonhomogeneous material properties.

Studies carried out by the Interdepartmental Laboratory of Numerical Modeling are aimed to create computational models of plant tissues at different spatial scales.

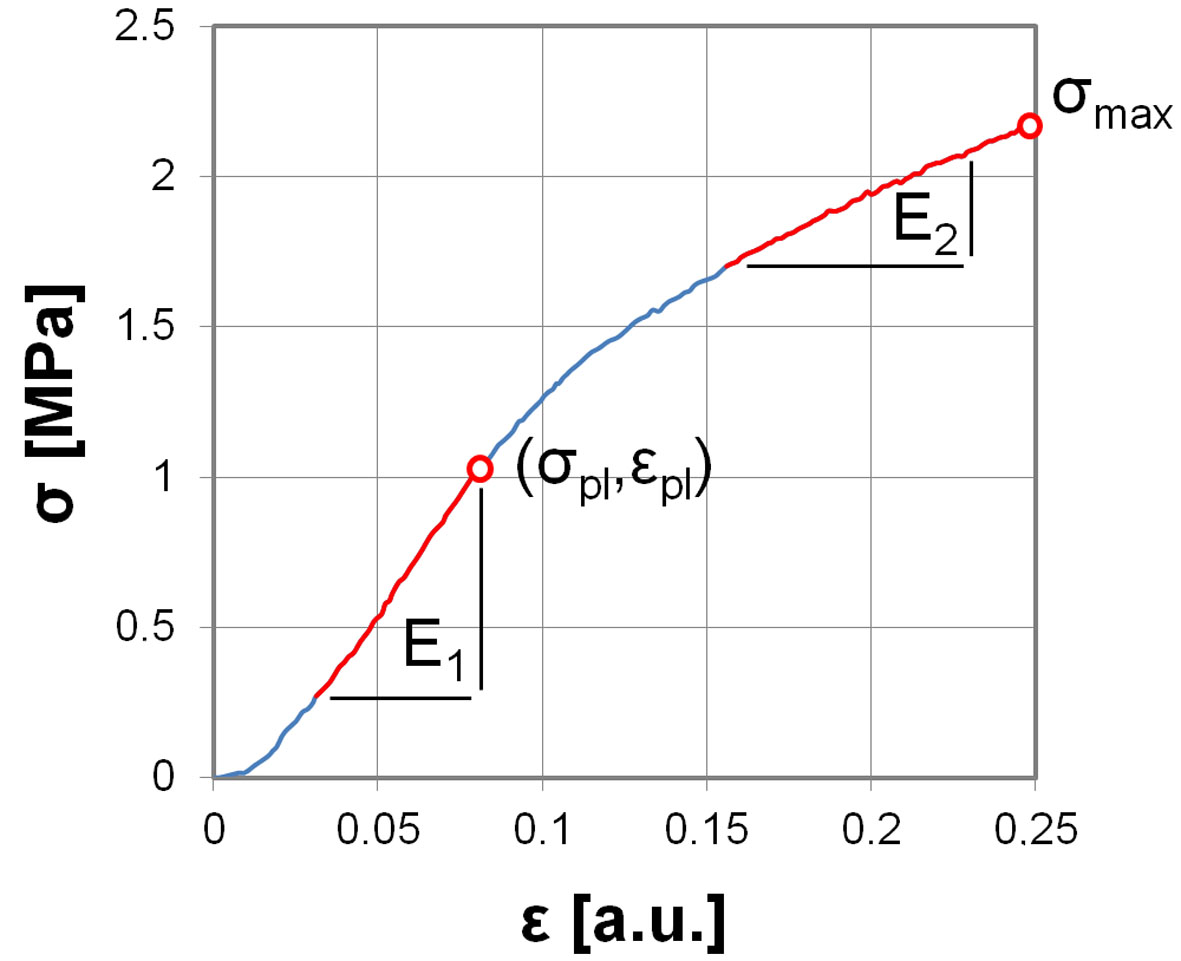

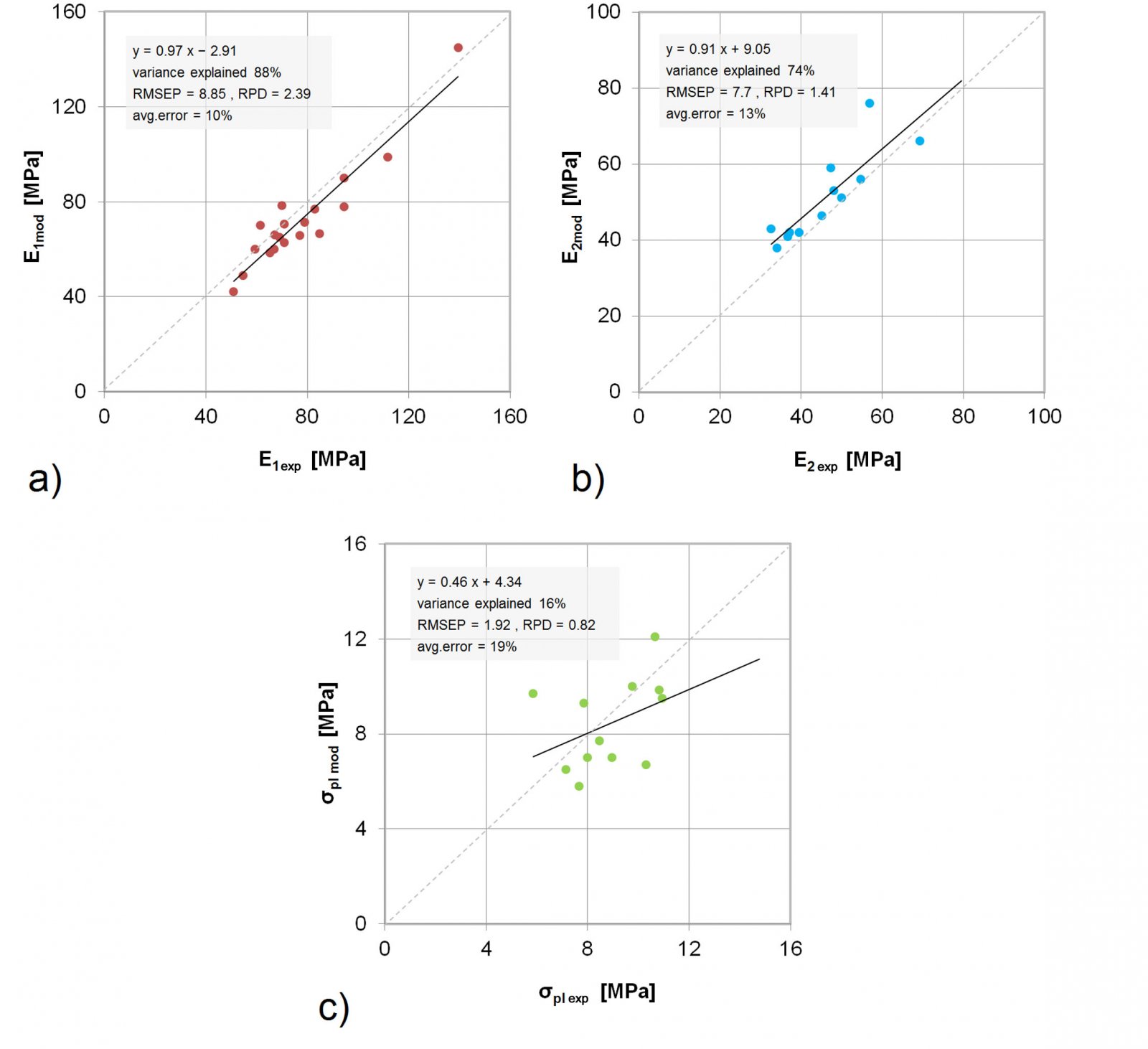

Modelling of plant tissues mechanical properties

Physical properties plant materials are related to several micro- and macroscopic morphological features such as the spatial arrangement and shape of cells, the number of intercellular spaces, turgor, the nano-composition of cell walls and the degree of degradation of the middle lamellae. The experimental analysis of the structure related micromechanical properties of plants has been constrained by the lack of technology available for conducting reliable measurements at such scales. Deeper understanding of mechanical properties of plant tissues can be achieved by means of the numerical models of tissue deformation under various load conditions.

Up to now, the majority of models described in the literature was based on the principles of classical continuum mechanics. Most often, tissues were described by empirical or analytical models, as uniformly stressed structures, with symmetry and uniformity assumptions on cell shape and cell wall deformations. Although this approach allowed for fairly accurate predictions of the behavior of the plant materials in engineering applications, it was unable to provide an explanation of the micro-scale mechanisms underlying deformation and failure of tissue.

The research was co-founded by National Science Centre of Poland (research grant no. 2011/01/N/NZ9/02496).

Tissue structure modelling

One of the important steps in solving a problem, before the appropriate analysis with FEM, is to create a virtual model of the tested object. The virtual model is defined by its geometry, material properties and boundary conditions such as loads and the type of supports. It is important to create a proper model with the highest possible degree of accuracy regarding real shape reconstruction; but on the other hand, the model must be simple enough to allow for efficient calculations.

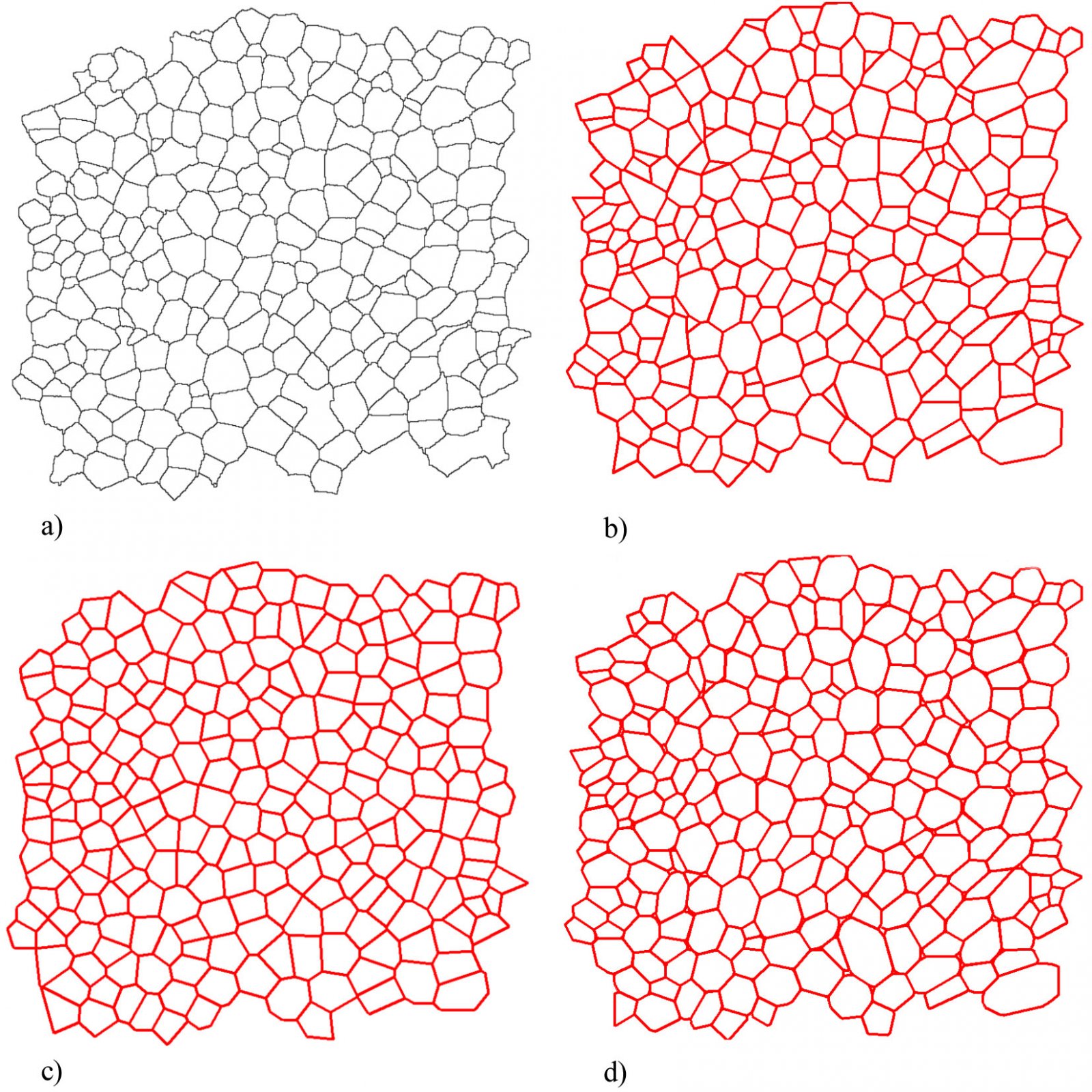

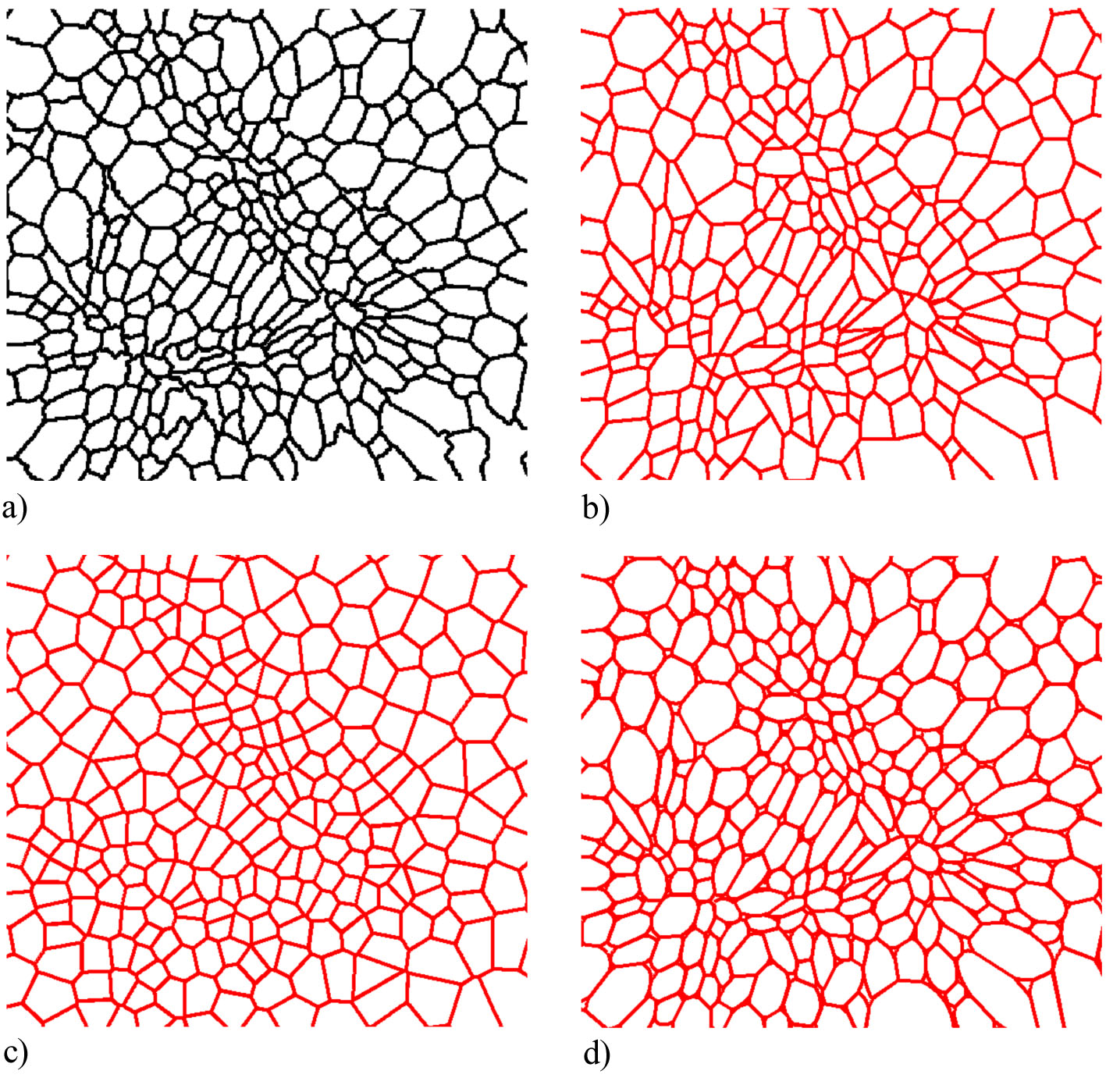

In the preliminary study three different methods for parameterisation of plant tissues were tested (Pieczywek et al., 2011). All methods can be applied to images obtained with a confocal scanning laser microscope to create models for the simulation of the mechanical behaviour of biological cellular structures. Vectorisation, Voronoi tessellation and ellipse tessellation were tested. Potato tuber and carrot parenchyma were chosen as examples.